Aerospace

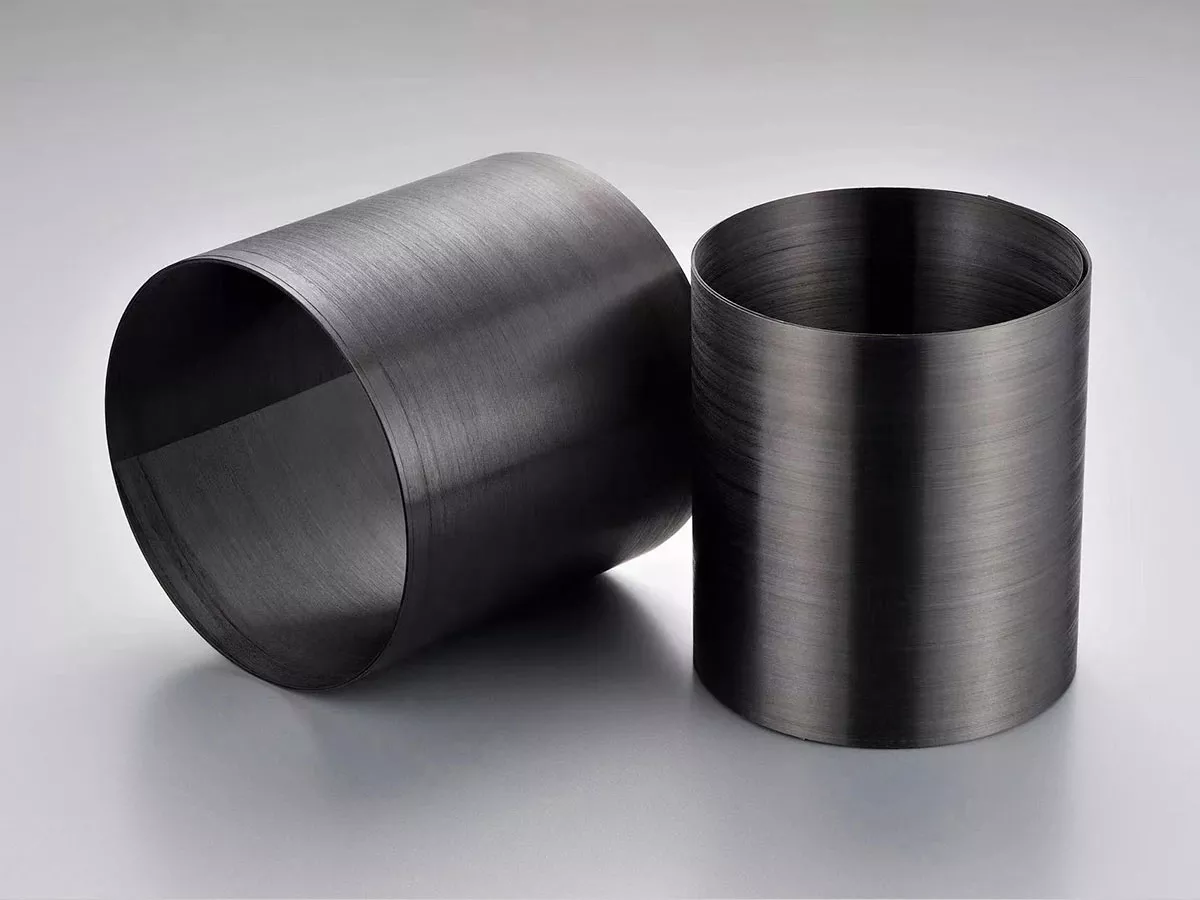

PFLUON PEEK is featured with low density, high strength, fatigue resistance, high temperature resistance, low temperature resistance, low smokiness, flaming retarding and non-toxicity. It is an ideal material for aerospace aircraft lightweight. It reduces weight by 27% when replacing aluminum alloy. The PEEK pure material brand and modified reinforced brand have been applied to aircraft pipeline clamps, floor brackets, wing leading edge, TAB heat insulation and sound insulation blankets, threaded fasteners, electronic connectors, oxygen cylinder brackets, radar hoods, aviation gasoline tank covers, aviation seat components, etc. The PFLUON PEEK 8200G film has been successfully applied to space aircrafts. The PFLUON PEEK 8800UFP continuous carbon fiber composite material has been applied to the main structural parts in the aviation industry thanks to its ultra-high mechanical strength and excellent fatigue performance. In the future, more PFLUON PEEK composites will be used in the aerospace industry, enabling aircrafts to “fly lighter, longer, safer, with more comfort and be more environmentally friendly.”