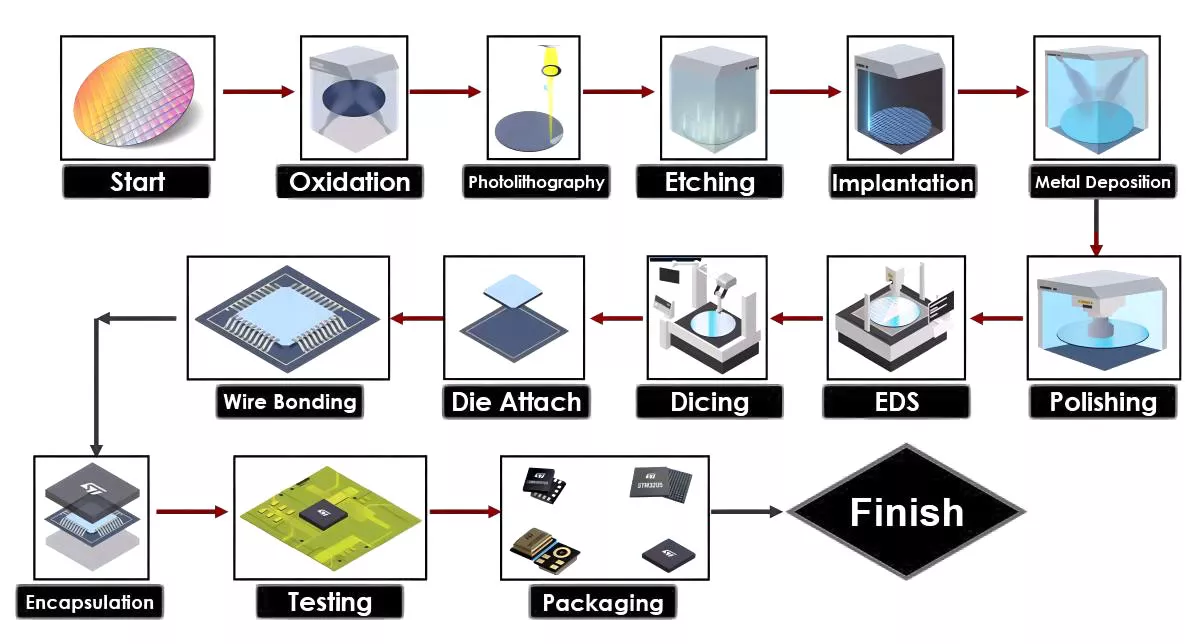

Semiconductors

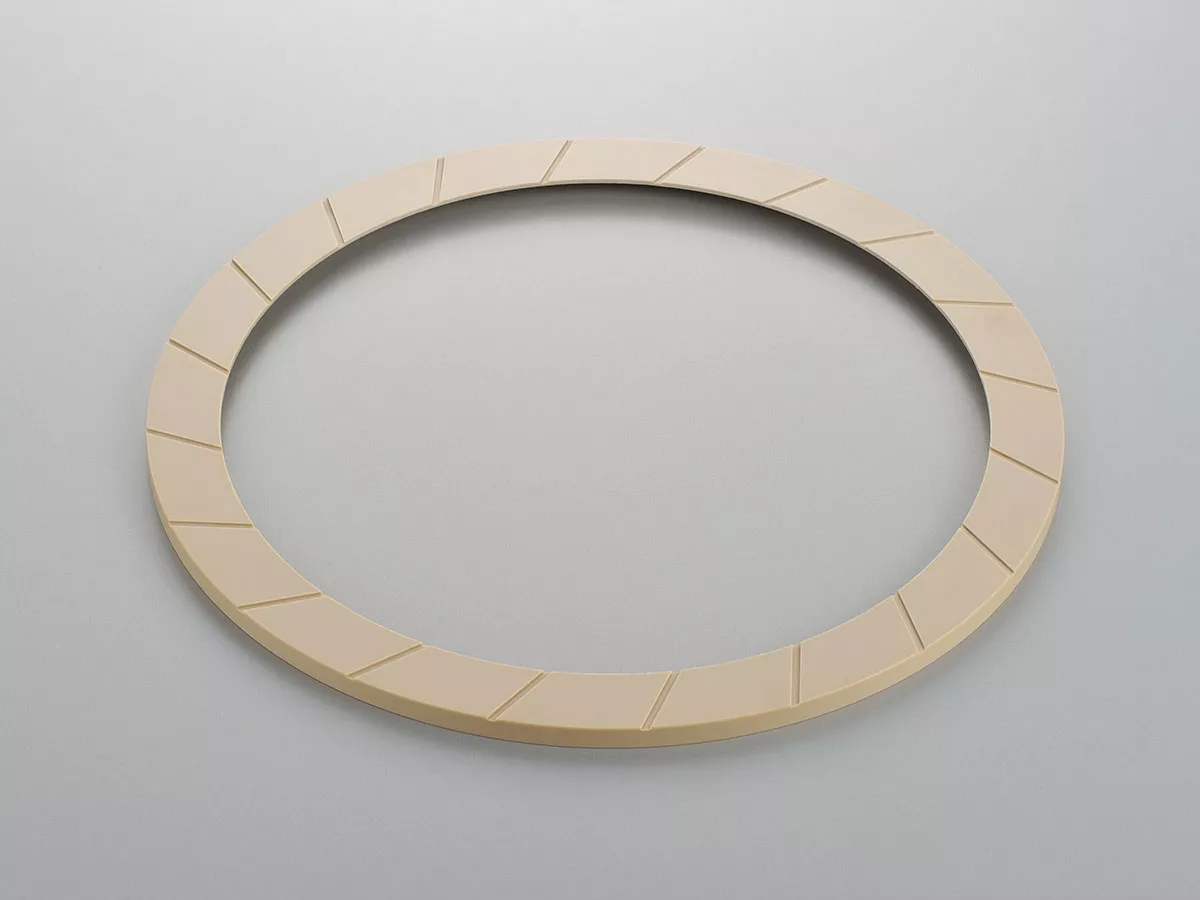

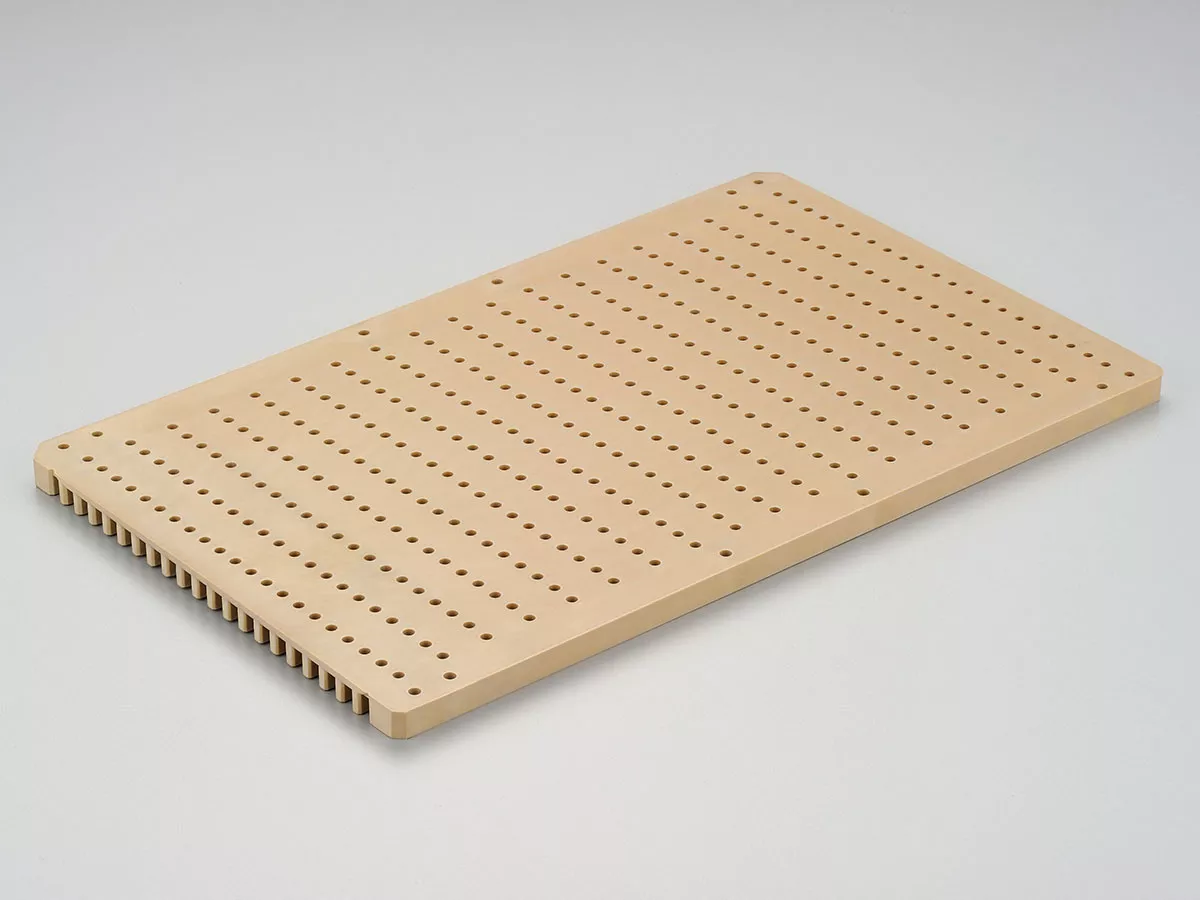

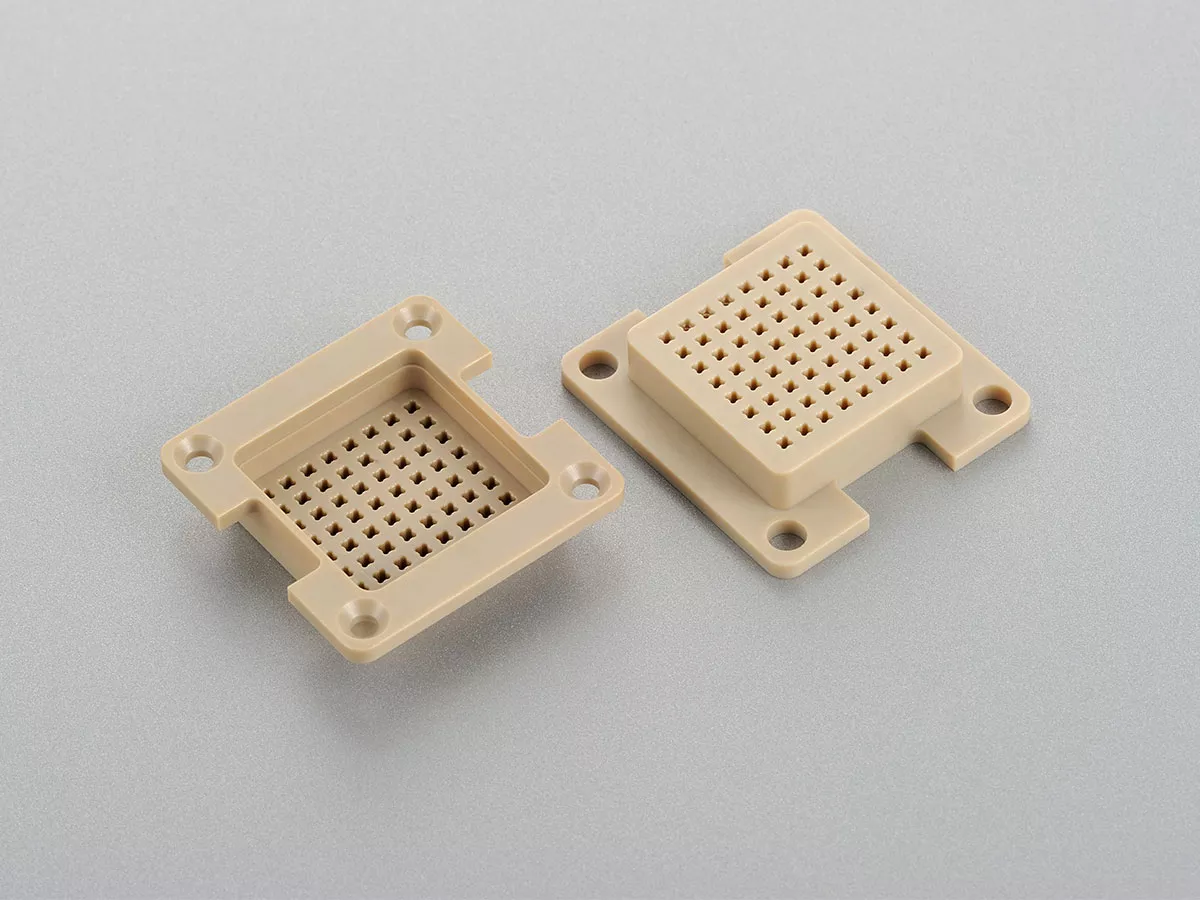

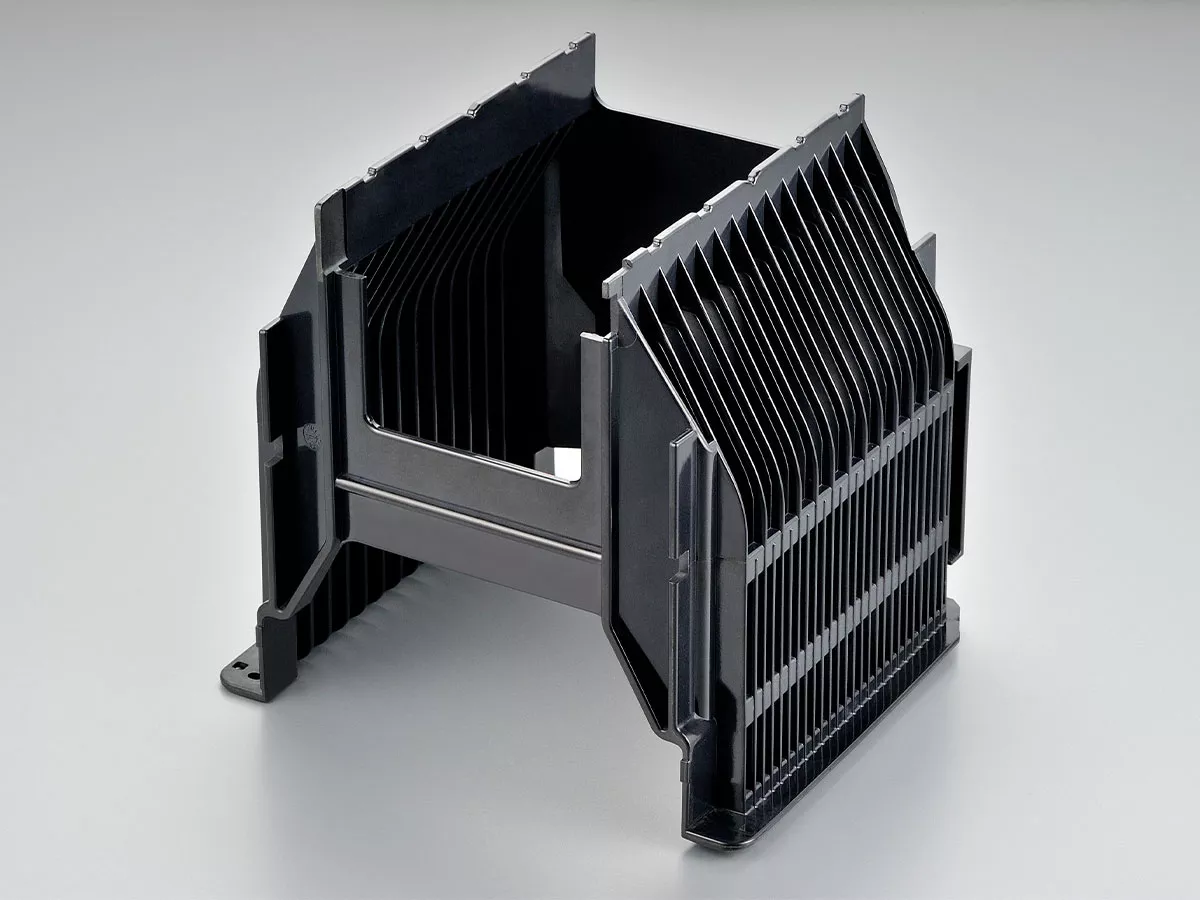

PFLUON PEEK can replace metals, incorporate parts (molded in one go) and simplify structures. Parts molded from PFLUON PEEK have low shrinkage and hygroscopicity, which meet high precision requirements in these applications.

PFLUON PEEK can also be composite processed into glass fibers, carbon fibers, graphite, additional modification of PTFE, special wear-resistant specifications or prepared for conductive and antistatic specifications.

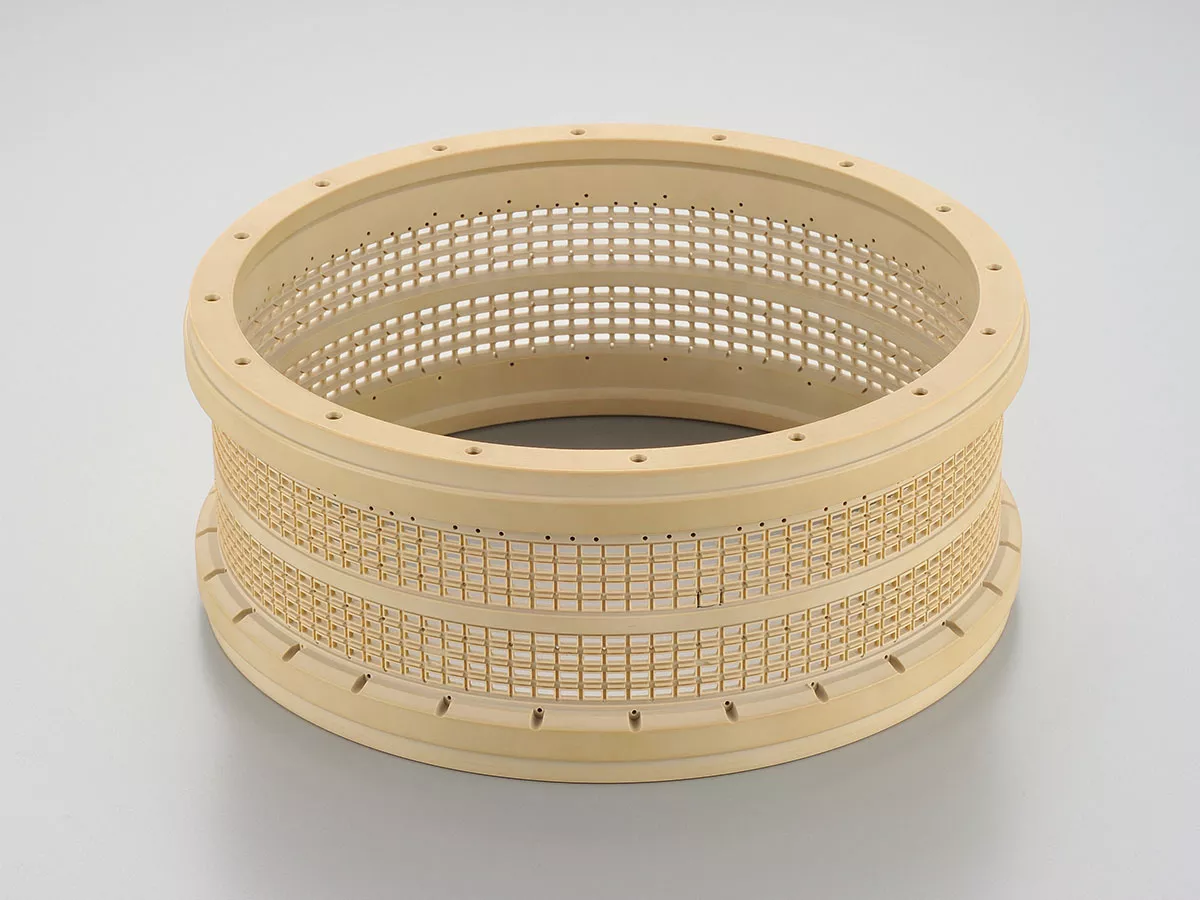

In addition, PFLUON PEEK provides materials of high-purity specifications that can be used in he semiconductor industry, especially for high temperature treated conditions. They have dimensional stability at both high and low temperatures, which ensures a clean surface, contamination-free, and corrosion-free from irritating chemicals and various solvents.