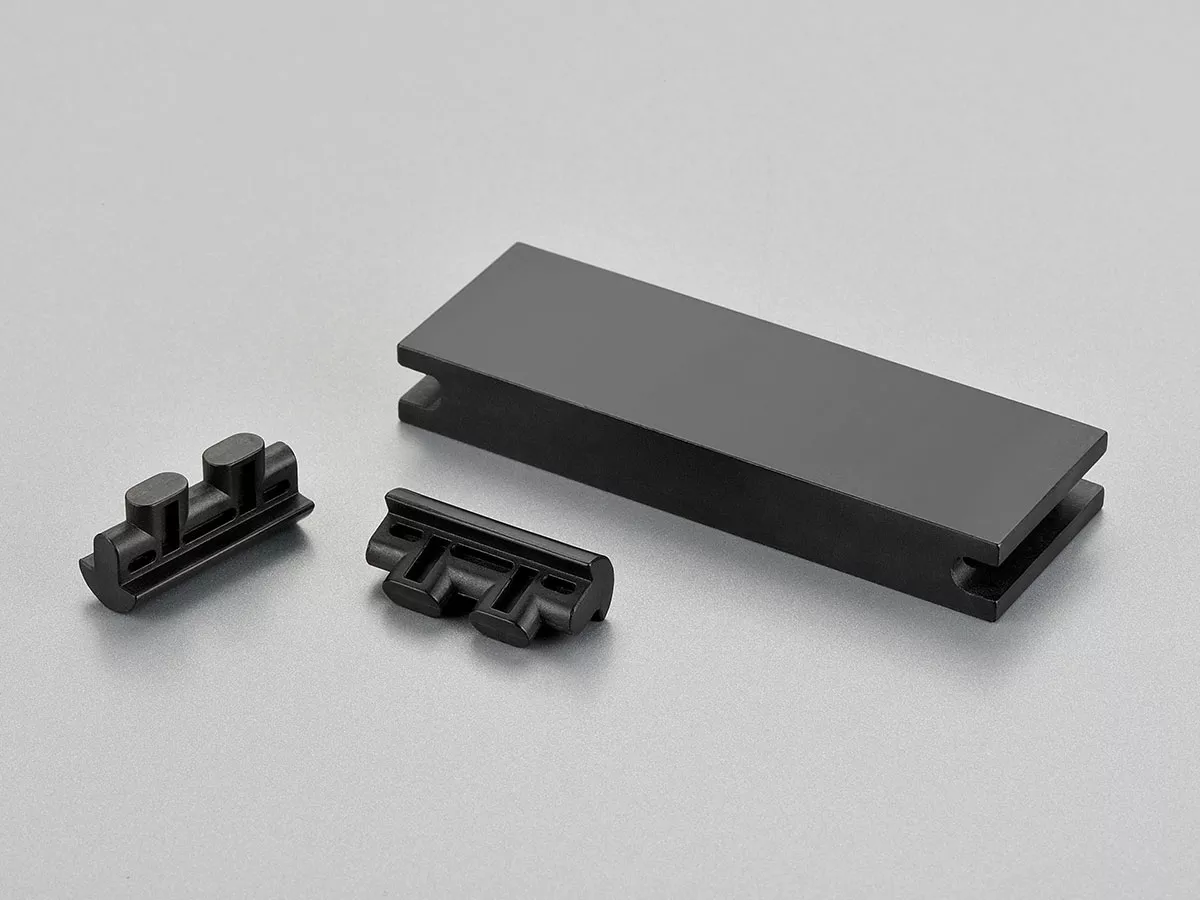

The PEEK polymer itself has a wide range of comprehensive performance advantages. After blending modification, a variety of brands that focus on one single performance have been developed. They are applied in different automotive systems and satisfy special functions of each application. So far, brands with various performance such as high wear resistance, high strength, high temperature resistance, low friction coefficient, impact resistance, fatigue resistance, high mobility etc. have been developed in the PEEK industry. They can meet application needs of six systems in traditional fuel vehicles, such as engines, transmission, suspension/steering, brake, fuel, HAVC. Over 50 PEEK components have been commercialized thus far. In recent years, with the rise of new energy vehicles, PEEK’s comprehensive performance advantages have been recognized by the new energy automobile industry. More and more PEEK new applications have been successfully developed in lithium-ion battery and hydrogen fuel cell vehicles.

/

/

/

/

/

/

/

/

/

/

/