- Tg = 143℃

- Tm = 343℃

- Continuous use temperature (CUT) : 260℃ (no load)

- Heat deflection temperature (HDT) of pure PEEK::

- Heat deflection temperature (HDT) of glass fiber reinforced PEEK: 310℃

- Heat deflection temperature (HDT) of carbon fiber reinforced PEEK : 320℃

High-performance polymer PEEK products

and application solutions

Scroll Down

PEEK High-performance Polymer

Polyether ether ketone (PEEK) is one of the most widely used high-performance polymers in the poly aryl ether resin family. As a semi-crystalline thermoplastic polymer, it has advantages such as high-temperature resistance, low-temperature resistance, wear resistance, high strength, corrosion resistance, gamma ray radiation resistance, fatigue resistance, easy forming etc. It is a high-performance polymer with the best comprehensive performance.

Introduction to the PEEK Performance

High-temperature resistance:

Low-temperature resistance

- -Good mechanical properties is maintained at 196℃

Radiation resistance

Good insulation ability and mechanical properties are maintained in γ irradiation dose up to 1100Mrad.

High strength

The reinforced PEEK has a specific strength higher than steel, aluminum alloy and other metals.

Fatigue resistance

With outstanding fatigue resistance under alternating stress and suitable for extreme fatigue scenarios such as long cycle gears.

Creep resistance

PEEK has a 1000h creep variable of <0.5% at a stress of 50% tensile strength.

Wear resistance

Excellent sliding properties, suitable for applications with strict requirements for low friction coefficient and wear resistance.

Chemical corrosion resistance

PEEK is insoluble in any solvent, strong acid or strong base except concentrated sulfuric acid. It is too hydrolysis resistant.

Excellent electrical performance

With good electrical insulation performance in a wide temperature range, and its dielectric loss is very small at high frequency.

Excellent thermal stability

Injection molding, extrusion and other processing is possible in a wide temperature range of 340~420℃. The thermal decomposition temperature is as high as 550℃.

Excellent biocompatibility

PEEK has excellent biocompatibility and no side effects, in compliance with all the requirements of the ISO10993 standard.

Low smokiness and flaming retarding

Among plastics, PEEK has low smokiness without any flame retardant, with a UL standard of 94V-0.

Low density

1.3g/cm3, the density of the modified material is much lower than that of metals of the same strength.

PFLUON PEEK

PFLUON PEEK

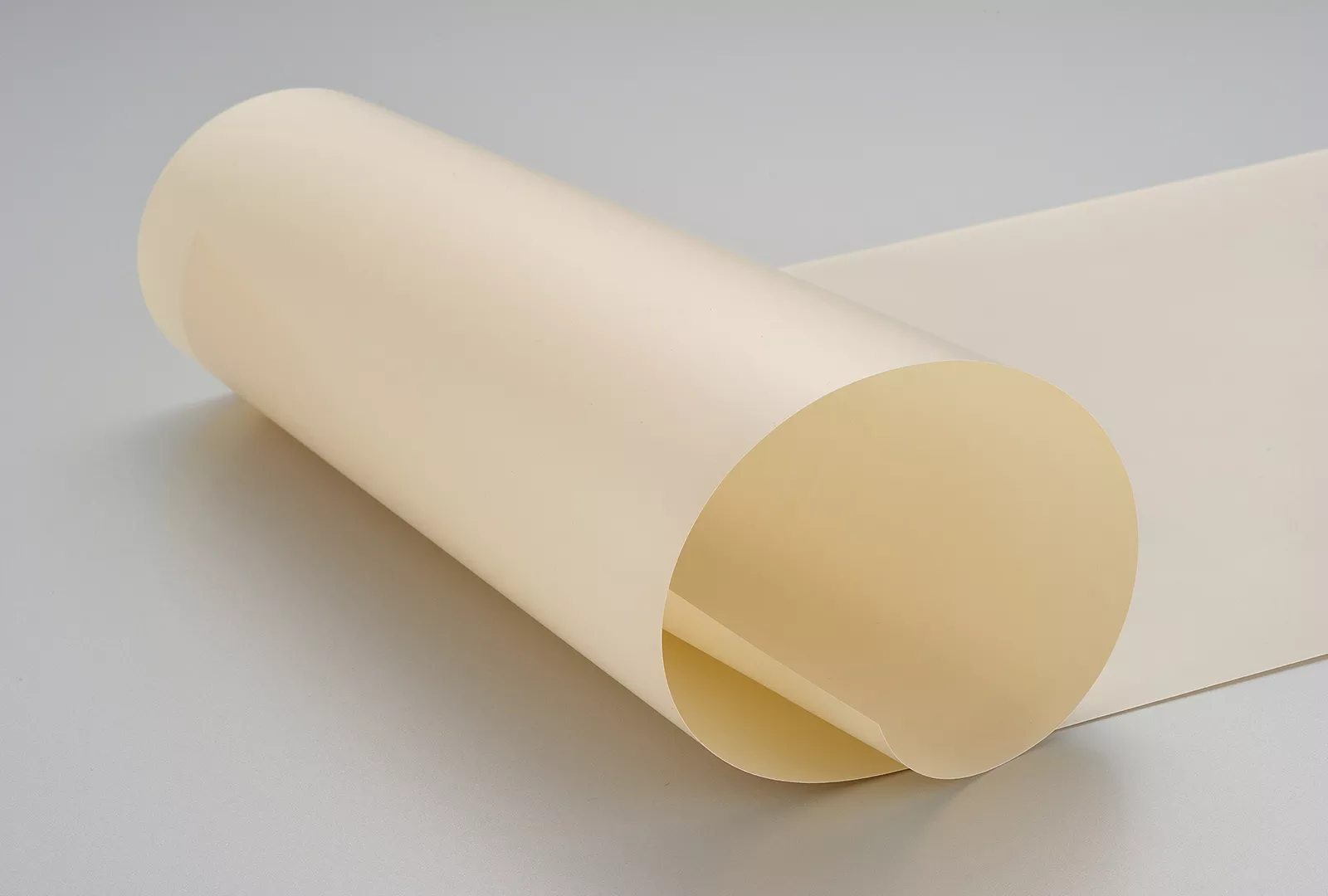

Pure resin

High toughness, fatigue resistance and insulation

- The brand with the right fluidity may be chosen according to the product specification size and processing method

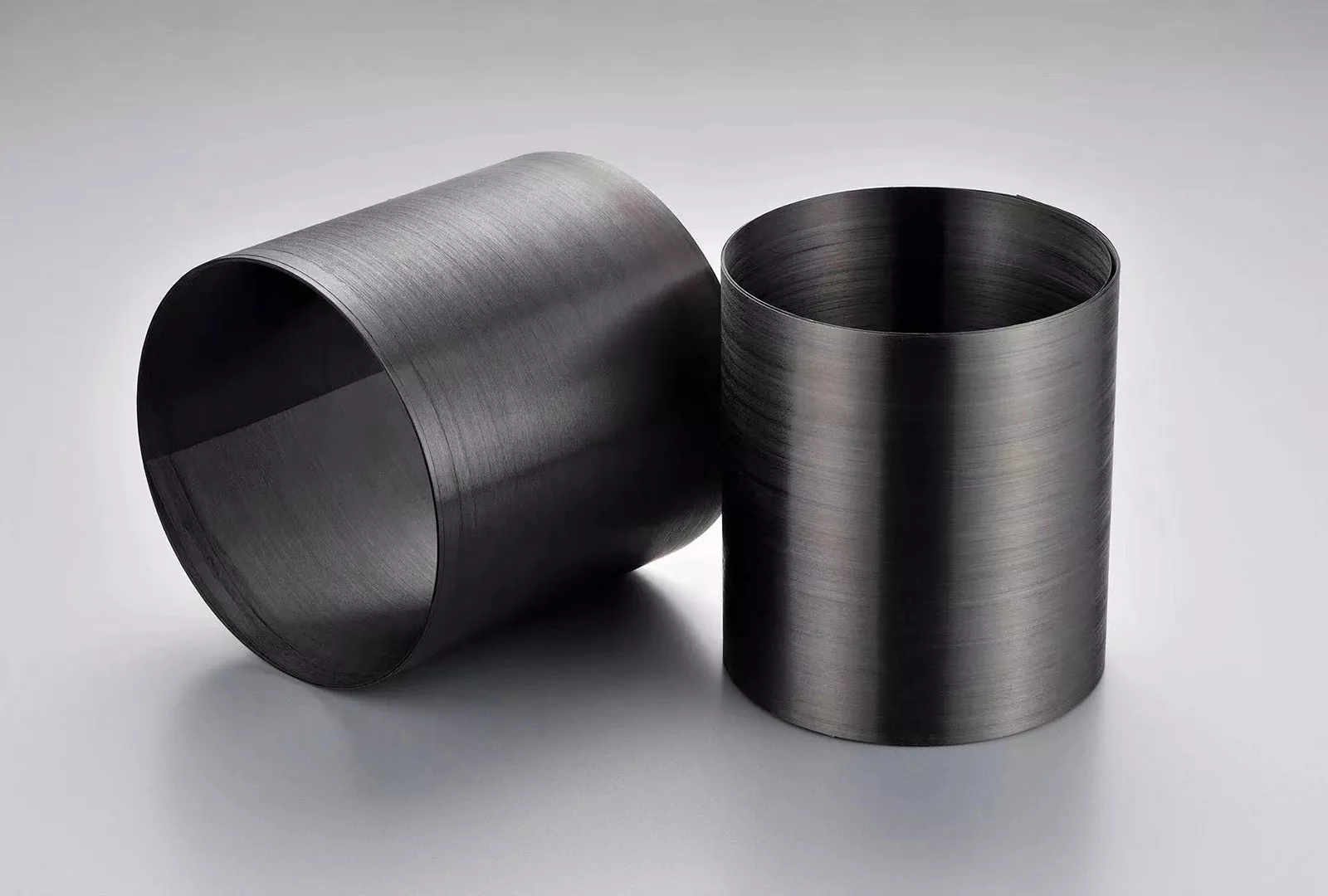

Carbon fiber reinforced PEEK

High strength, temperature resistance and wear resistance

- Carbon fiber filling up to 50%.

- The tensile strength of conventional CF30 PEEK is 240~260Mpa, and that of the high-strength CF30 PEEK is up to 300Mpa.

- Commonly used brands: 8200CF30 8800CF30

Glass fiber reinforced PEEK

Impact resistance, temperature resistance, high strength, cost reduction

- Glass fiber filling up to 60%.

- The tensile strength of conventional GF30 PEEK is 170~190Mpa, and that of the high-strength GF30 PEEK is up to 215Mpa.

- Commonly used brands:8200GF30 8800GF30 8800GF30B FB908

Wear-resistant PEEK

Wear-resistant and self-lubricating

- Wear-resisting working conditions are complex, such as high pressure and high speed, high pressure and low speed, low pressure and high speed, lubricating medium, relative wear materials, wear amount, working temperature... Different working conditions pose different material formula requirements and customized solutions are needed.

- Currently, the composite modified wear-resistant PEEK has the lowest friction coefficient of 0.12.

- Commonly used brands:8200FC30 8800FC30 8200CF30 8800CF30 HE611 HW002 8800WF45

Antistatic PEEK

Antistatic

- The surface resistivity is uniform and controllable to meet the conventional requirements of 105-8 Ω/m2.

- Different formulas may be provided based on to different application requirements.

- Commonly used brands:ESD802 ESD806

Ceramic PEEK

Excellent dimensional stability

- Nano ceramic filling, excellent dimensional stability, can be used for semiconductor chip test box, processing with micro pores and no burr, no deformation.

- PFLUON Ceramic PEEK retains the original toughness and strength of PEEK

- Commonly used brands:HDR425

PEEK with low thermal conductivity

Heat insulation

- Thermal conductivity as low as Wm-1K-1, can be used in applications requiring heat insulation

- Commonly used brands:HDR410

Voltage-resistant PEEK

High voltage resistance

- Has high dielectric strength and excellent electrical insulation performance, can be used for insulation parts under extremely high voltage.

- Commonly used brands:FB917

Recommended PFLUON PEEK products

for various applications

Processing Common Problems & Analysis

Pfluon Non-Stick Ceramic Coatings: How we Make Our Ceramic Coating on Cookware

When communicating with our customers, there are questions about our ceramic coating products. Our sales team is always ready to provide answers, and if necessary, our technical staff will visit…

Analysis of common issues in molding processing

1、Vacuum pores. The main reason may be lack of pressure, including during cold pressing, hot pressing, cooling stage, etc. A reasonable mold pressure should be set. It may also be…

Analysis of common issues in extrusion processing

1、 No materials fed, including no materials fed into the hopper area and no materials fed into the screw feeding section. If no materials are fed into the hopper area,…

Analysis of common issues in injection molding

1、Transparent or uneven-colored pure resin parts. The transparent or uneven color of the parts is caused by insufficient crystallinity or inconsistent crystallinity of the materials. The issue can be optimized…

Our Turnkey Services

Consultation/Service Application Form

Consult immediately

Scan the code to follow the Wechat official account