Appliance cookware

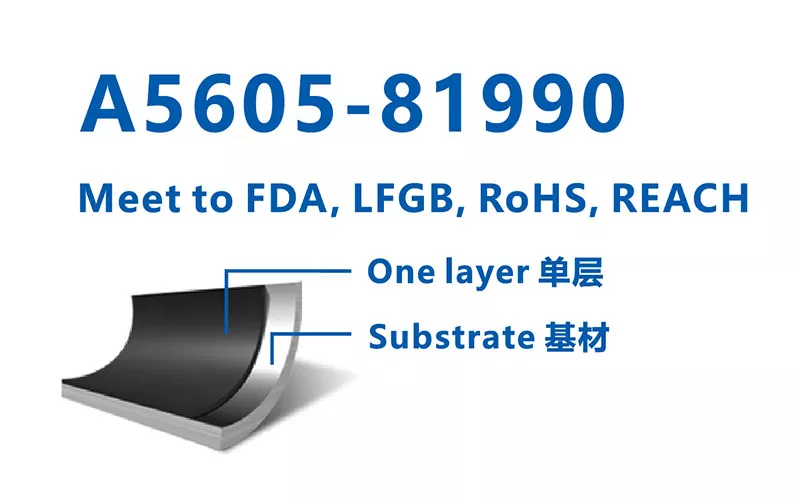

Innovative materials and technologies provide consumers with aesthetically comfortable and durable experience.

Innovative materials and technologies provide consumers with aesthetically comfortable and durable experience.

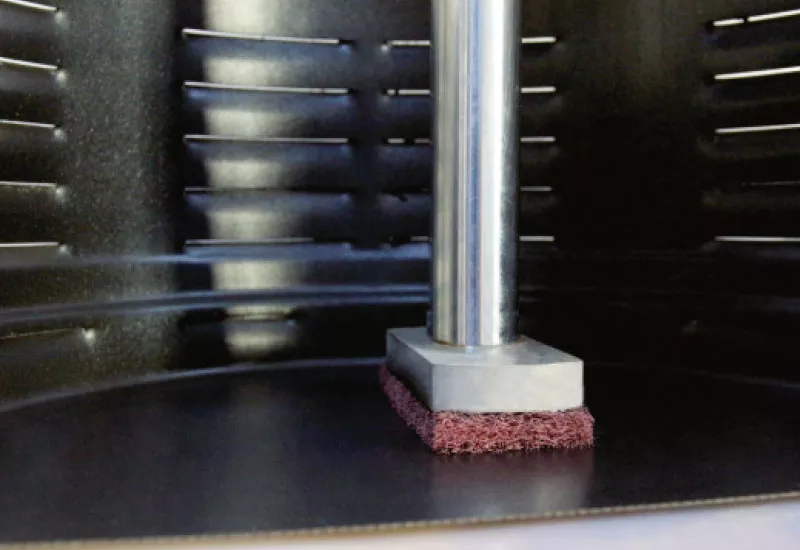

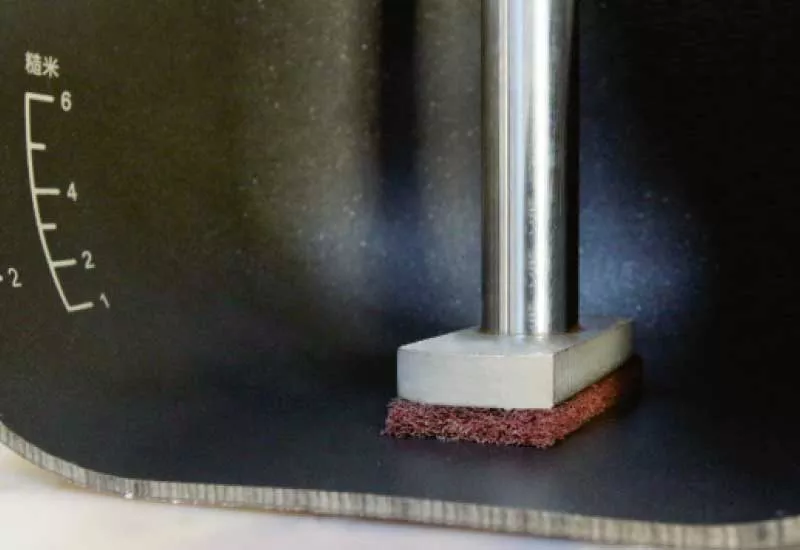

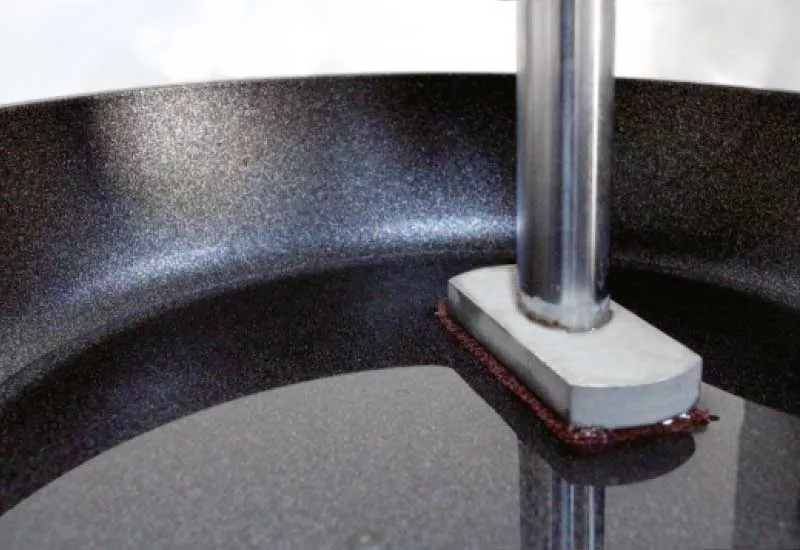

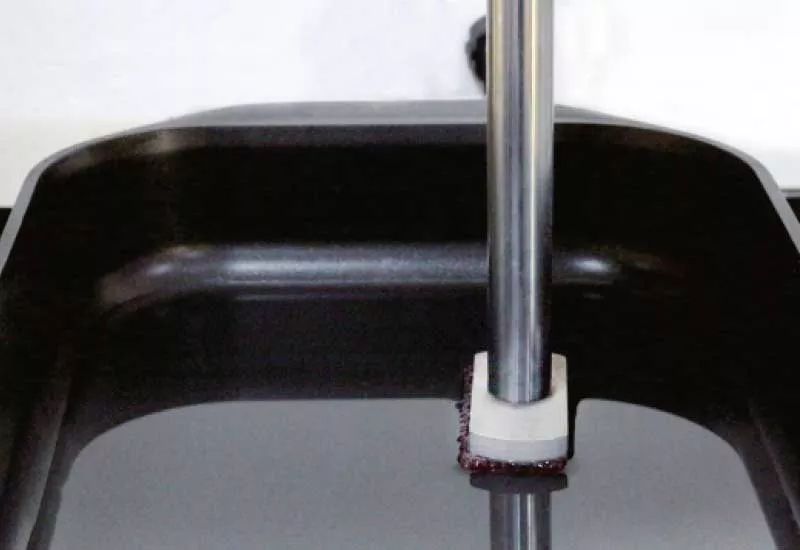

wear resistance

Use 30N/21cm² wear-resistant pad (3M-7447B) and do wet milling with 5% detergent. If there are grinding marks which are exceeded to 1mm or 5 linear grinding marks with a length that longer than 2mm on the surface of the non-stick coating, the experiment shall be stopped.

Dishwasher testing

Use 70 grams of detergent/ washing powder and set machine at 70 ℃ for 120 minutes for one work cycle. After 150 cycles, there is no peeling or bubbles in the coating.

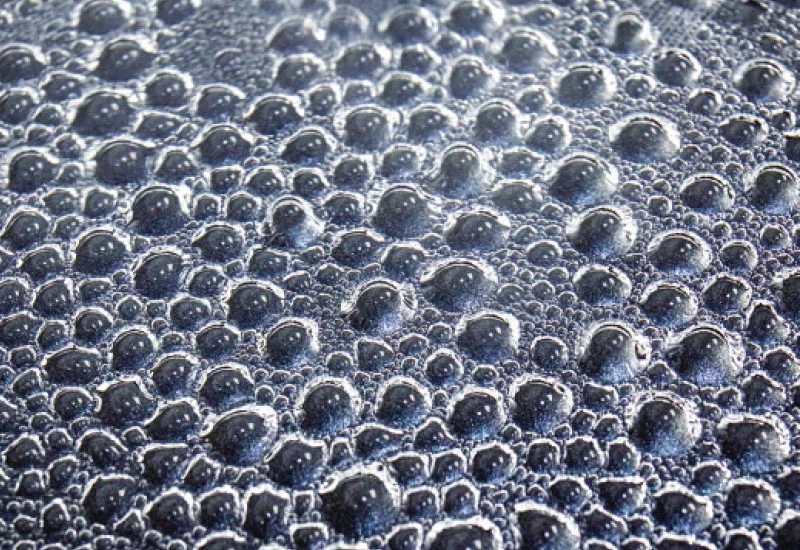

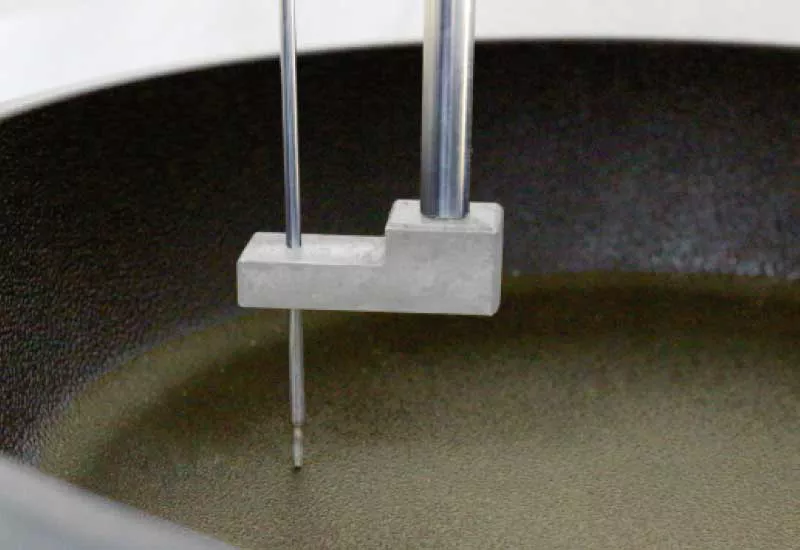

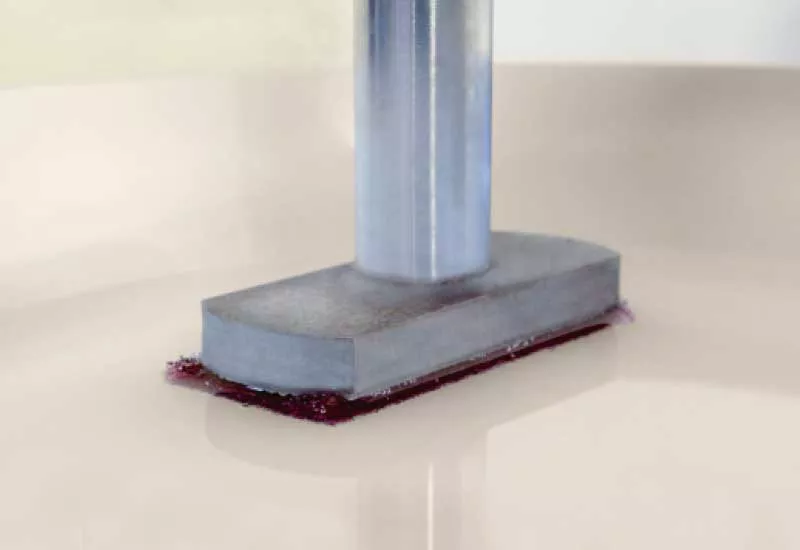

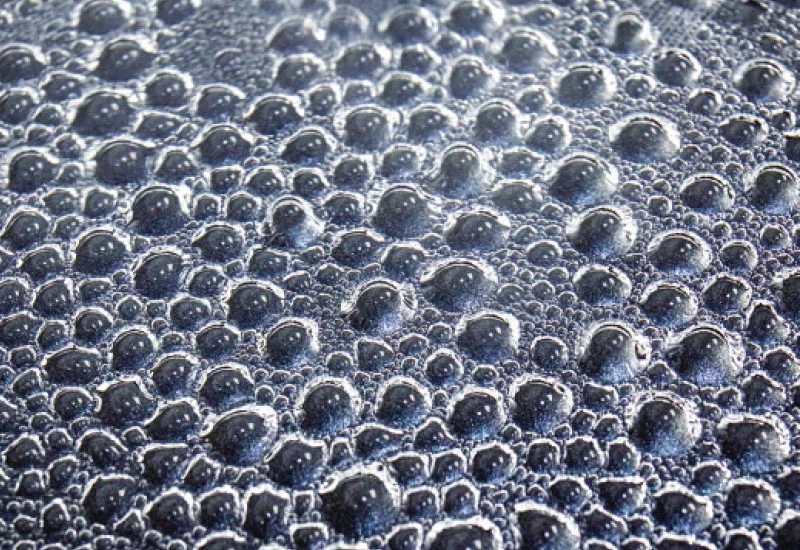

corrosion resistance

Use 10% mass fraction of salt water and keep slightly boiling for 24 hours. The coating should be free of defects such as bubbles and peeling.

wear resistance

Use 30N/21cm² wear-resistant pad (3M-7447B) and do wet milling with 5% detergent. If there are grinding marks which are exceeded to 1mm or 5 linear grinding marks with a length that longer than 2mm on the surface of the non-stick coating, the experiment shall be stopped.

hardness

Use Zhonghua pencil and push 750g pencil hardness tester at least 7mm, the hardness of the first pencil that has not scratched the coating is the test result.

corrosion resistance

Use 10% mass fraction of salt water and keep slightly boiling for 24 hours. The coating should be free of defects such as bubbles and peeling.

Test for cooking soy sauce:

Use the proportion of water:soy sauce:salt=100:7:3 and heat the sample continuously for 150 hours and observe the surface coating for defects such as bubbles and erosion.

Wear resistance

Use 30N/21cm² wear-resistant pad (3M-7447B) and do wet milling with 5% detergent. If there are grinding marks which are exceeded to 1mm or 5 linear grinding marks with a length that longer than 2mm on the surface of the non-stick coating, the experiment shall be stopped.

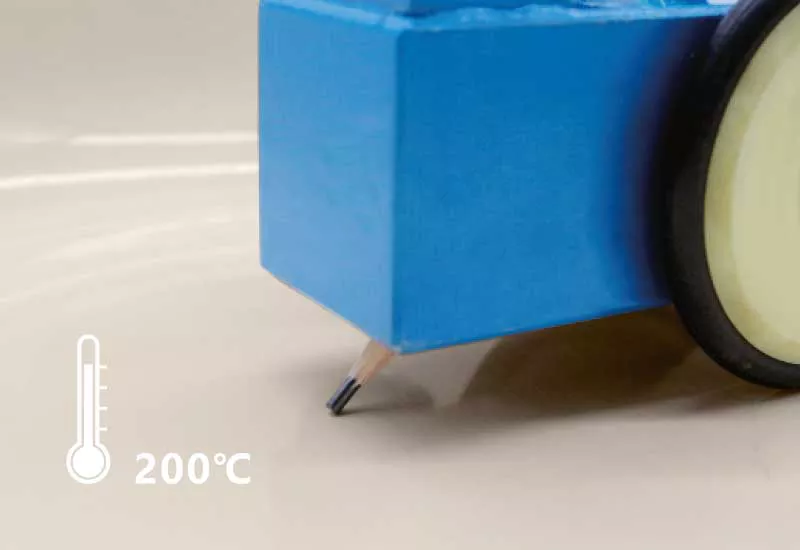

Tiger’s claw test:

Use PARKER ballpoint pen refill (115mm, diameter 0.5mm) with a load of 400g and make the temperature of substrate to 200 ± 10 ℃. Record the time when the coating is scratched and the substrate is exposed.

Simulated cooking test:

Simulate normal cooking using rice from Northeast China. After cooking, keep it warm for 10 minutes, then invert the inner container and record the number of spots of peelings from the surface oil coating.

Wear resistance

Use 30N/21cm² wear-resistant pad (3M-7447B) and do wet milling with 5% detergent. If there are grinding marks which are exceeded to 1mm or 5 linear grinding marks with a length that longer than 2mm on the surface of the non-stick coating, the experiment shall be stopped.

Tiger’s claw test

Use PARKER ballpoint pen refill (115mm, diameter 0.5mm) with a load of 400g and make the temperature of substrate to 200 ± 10 ℃. Record the time when the coating is scratched and the substrate is exposed.

Hot hardness

Use PARKER ballpoint pen refill (115mm, diameter 0.5mm) with a load of 400g and heat the temperature of substrate to 200 ± 10 ℃. Record the time when the coating is scratched and the substrate is exposed.

Hot hardness

Heat the coating to 200℃ and use Zhonghua pencil to push 25mm, the hardness of the first pencil that has not scratched the coating is the test result.

Wear resistance

Use 30N/21 cm² wear-resistant pad (3M-7447B) and do wet milling with 5% detergent. If there are grinding marks which are exceeded to 1mm or 5 linear grinding marks with a length that longer than 2mm on the surface of the non-stick coating, the experiment shall be stopped.

emperature resistance

Dishwasher testing

Use 70 grams of detergent/ washing powder and set machine at 70 ℃ for 120 minutes for one work cycle. After 150 cycles, there is no peeling or bubbles in the coating.

corrosion resistance

Use 10% mass fraction of salt water and keep slightly boiling for 24 hours. The coating should be free of defects such as bubbles and peeling.

wear resistance

Use 30N/21 cm² wear-resistant pad (3M-7447B) and do wet milling with 5% detergent. If there are grinding marks which are exceeded to 1mm or 5 linear grinding marks with a length that longer than 2mm on the surface of the non-stick coating, the experiment shall be stopped.

PFLUON industrial coating products use high-performance materials. When the coating is used in high load conditions, the substrate has sufficient hardness and yield strength, corrosion resistance, high hardness and low friction performance, high coating bonding strength, and long-term wear protection, suitable for protection and repair under various working conditions.