Non Stick Coating Insights

Non-Stick Coatings Industry Soars

The non-stick coatings industry has experienced remarkable growth in recent years, driven by increasing demand across various sectors. According to a report by Straits Research, the global non-stick coatings market was valued at USD 1,475.42 million in 2022 and is projected to reach USD 2,720.47 million by…

How to Improve Ceramic Non-Stick Coatings Performance Through Grafting Modification

Ceramic non-stick coatings are formed through the sol-gel method, which involves the hydrolysis, condensation, polymerization, and crosslinking of silica sol and silane monomers in the presence of organic or inorganic acid catalysts. This process results in the formation of an organic-inorganic composite coating with a ceramic…

Maturation in Non Stick Coatings Manufacturing Process

In the world of high-performance coatings, the concept of maturation plays a crucial, yet often overlooked, role in achieving flawless results. Maturation is a critical step that sets the stage for the successful integration of the coating’s key components, ultimately leading to a superior final product.…

Sandblasting in Making Non Stick Cooware

Non-stick cookware is everywhere in our kitchens, and it saves our time for cooking and cleaning. Today when people cook, people choose non stick coating cookware, no matter it’s TEFLON or Ceramic. But have you ever wondered how that slick, easy-to-clean coating is applied to pots…

PEEK Wire & Cable: The Future of High-Performance Electrical Insulation

In the ever-evolving world of electrical engineering, the demand for high-performance insulation materials continues to grow. Traditional materials like polyimide and polyester imide have served the industry well, but they come with limitations such as high water absorption rates and complex processing techniques. Enter PEEK (Polyether…

PLASTRON-W8538X: Pfluon’s Latest Non-Stick Coating

The PLASTRON series has long been Pfluon’s exceptional and durable non-stick coating product. As a crucial part of Pfluon’s non-stick coating portfolio, we continuously update and iterate this series with the latest technologies. At the second phase of the Canton Fair, we are excited to show…

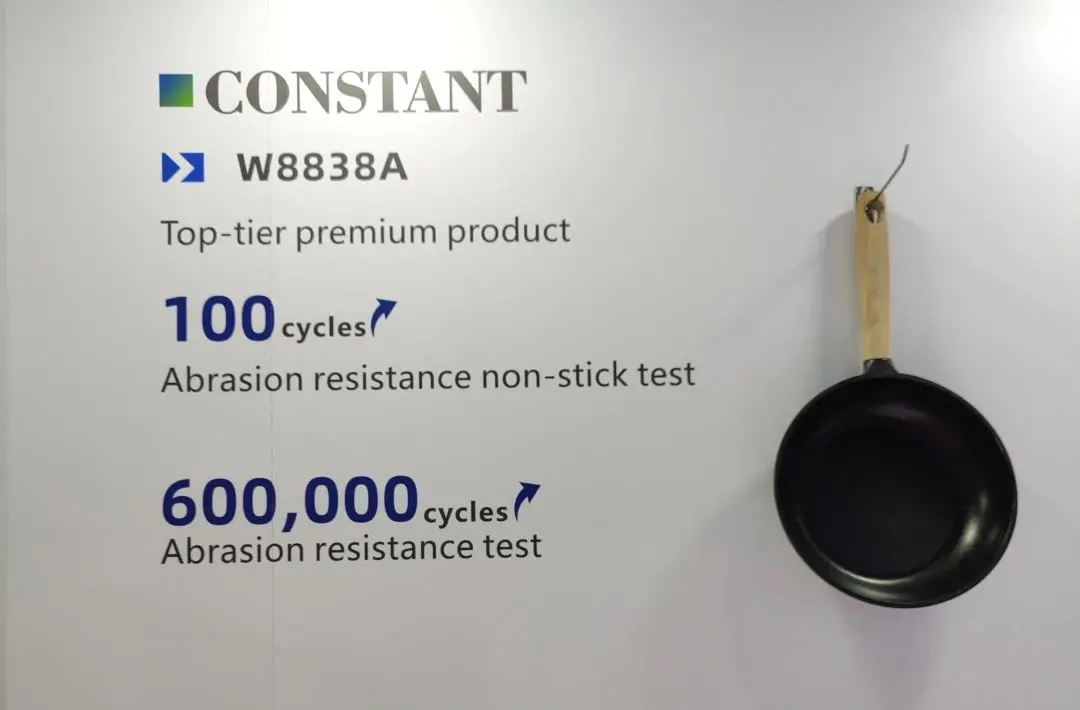

CONSTANT-W8838A: Pfluon’s Latest Non-Stick Coating

As Pfluon’s flagship high-end product, the CONSTANT series has always favored by numerous customers due to its exceptional quality and superior performance. As the performance representative of Pfluon’s non-stick coatings, we continuously update and iterate this series. At the second phase of the Canton Fair, we…

Pfluon Non-Stick Ceramic Coatings: How we Make Our Ceramic Coating on Cookware

When communicating with our customers, there are questions about our ceramic coating products. Our sales team is always ready to provide answers, and if necessary, our technical staff will visit the site to inspect and guide the process. To serve you better, we’ve prepared this content…

Substrate Pre-treatment in Non-stick Coating Manufacturing: A Comprehensive Guide

Non-stick coating industry has always been complex and it takes efforts to make the fine non stick coating. And among all the steps of non stick coating manufacturing process, substrate pretreatment is the key. In this comprehensive guide, we’ll dive deep into the world of substrate…

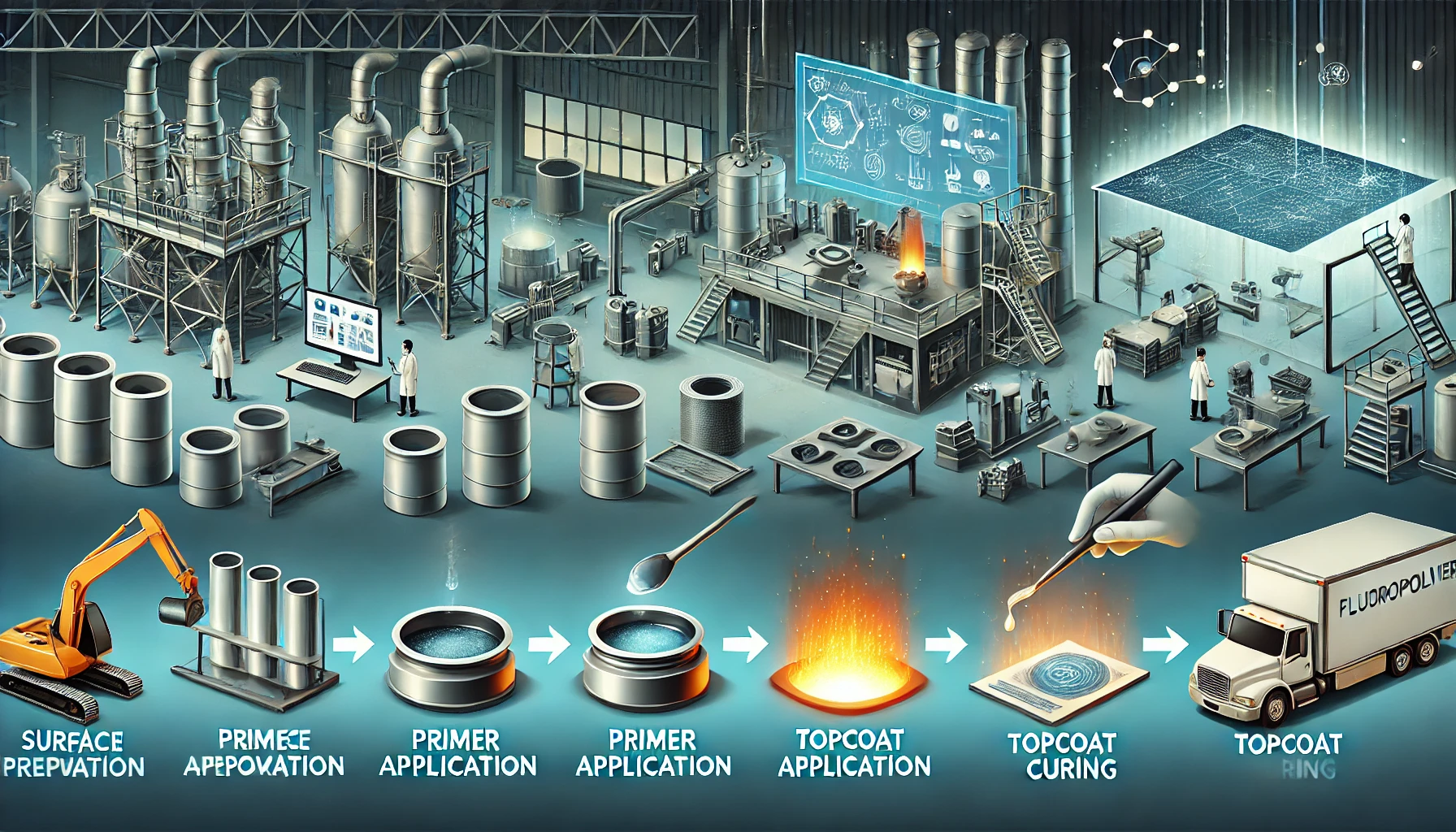

4 Steps of Fluoropolymer Coating Process

Fluoropolymer coatings are renowned for their exceptional resistance to chemicals, heat, and corrosion, making them ideal for various industrial applications. The process of applying fluoropolymer coatings involves several steps to ensure the coating adheres properly and performs optimally. This article provides a detailed overview of the…

Global Fluoropolymer Coatings Market

The fluoropolymer coatings market is a growing sector driven by the increasing demand for high-performance coatings in various industries. These coatings are known for their exceptional resistance to chemicals, heat, and corrosion, making them ideal for use in harsh environments. This article explores the current state…

Is Marble Coating Better Than Granite Coating Cookware?

Choosing the right cookware can significantly impact your cooking experience and the quality of your meals. Two popular options are marble-coated and granite-coated cookware. Both have their unique features, benefits, and potential drawbacks. This article compares marble and granite coatings to help you determine which is…