The Ceramic Non-stick Coating Series products are one of Pfluon's core offerings, embodying our relentless pursuit of quality and innovation. In our daily business communications, we always strive to provide our customers with comprehensive and detailed product knowledge, helping them fully understand the unique value of ceramic non-stick coatings.

In this issue, we will take a deep dive into the characteristics of ceramic non-stick coatings and answer several related questions.

What is Ceramic Non-stick Coating?

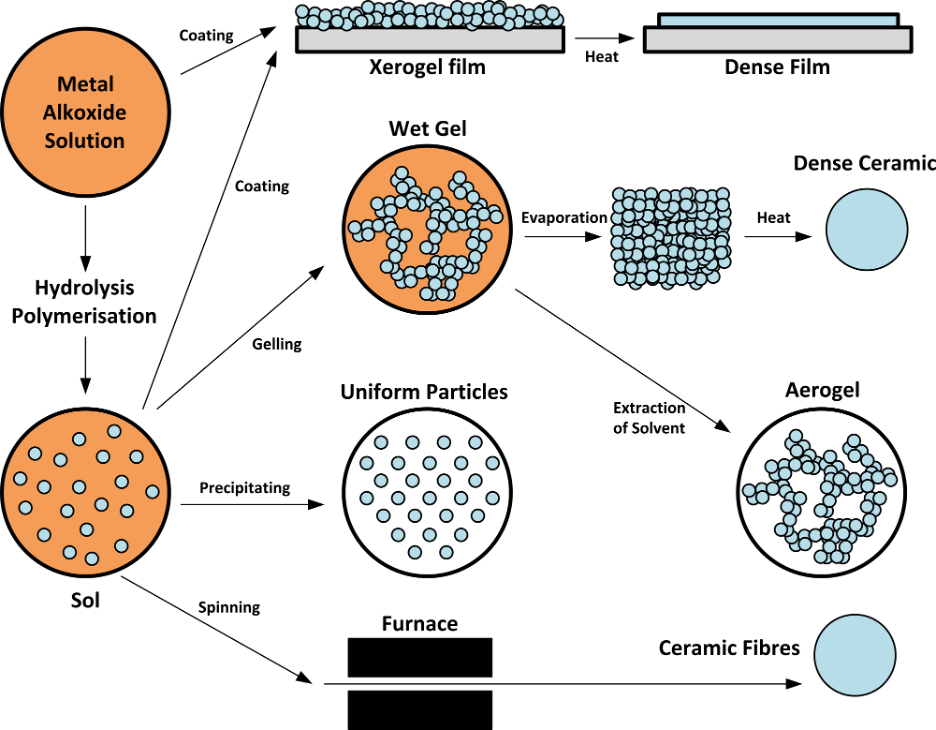

Ceramic non-stick coating is produced through the Sol-Gel process, mixing organic and inorganic substances. This non-stick coating is named "ceramic non-stick coating" due to its ceramic-like appearance and properties.

The Sol-Gel process involves chemically transforming a liquid precursor into a solid material, comprising two main stages: the formation of a sol and the transition to a gel.

- Sol phase: In this stage, inorganic or organic metal salts or metal-organic compounds are dissolved in a solvent (water or organic solvent) to form a uniform liquid solution. Under chemical reaction, these molecules begin to form colloidal particles known as a "sol."

- Gel phase: Over time or under specific catalytic conditions, sol particles gradually connect to form a three-dimensional network structure, a process called "gelation." During gelation, the solvent is enveloped by this network structure, resulting in a porous solid gel.

The manufacturing process of ceramic non-stick coatings through the Sol-Gel technique combines the flexibility and non-stick properties of organic polymers with the heat resistance and hardness of inorganic materials.

As a result, ceramic non-stick coatings can form a hard, wear-resistant, and high-temperature resistant coating on the surface of cooking utensils, providing superior cooking performance and lasting non-stick properties.

Source of Non-stickiness Ceramic Non-stick Coatings

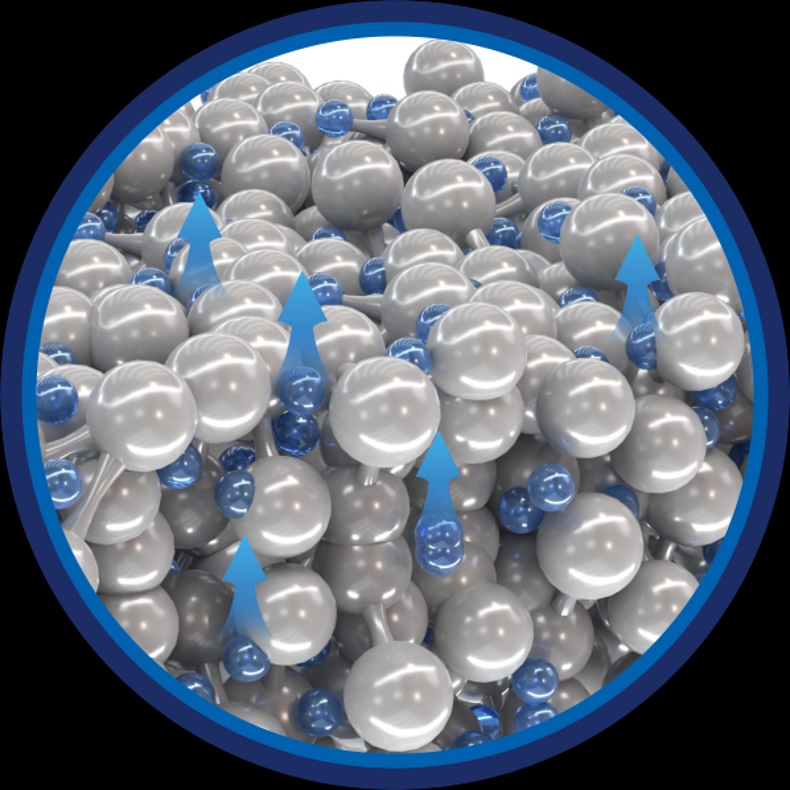

The non-stick property of ceramic non-stick coatings primarily comes from the inclusion of PDMS (Polydimethylsiloxane), a common silicone-based organic polymer.

In a previous article: Unveiling the World of PTFE Non-stick Coating Ingredients, we explained how the exceptional non-stickiness of water-based fluoropolymer coatings stems from its main component, PTFE, which has a very low surface energy (18Dyne/cm).

Similarly, the surface energy of PDMS in ceramic non-stick coatings is only slightly higher than PTFE, at 19-21Dyne/cm, endowing it with comparable non-stick performance.

Leveraging Pfluon's PDS enduring non-stick technology, the latest ceramic non-stick coating product, PFLUON Amber, exhibits even more exceptional lasting non-stick performance.

Over time, the non-stick substances in ceramic coatings gradually decompose and deplete. However, under Pfluon's PDS technology, silicone capsules can release non-stick substances more slowly and lastingly than conventional capsules, enhancing the product's lasting non-stick performance by 300% compared to conventional ceramic products.

Moreover, the non-stick property of ceramic non-stick coatings also helps reduce the amount of oil needed for cooking, facilitating the preparation of healthier low-fat diets.

The non-stick effect further reduces the need for detergents and water in the cleaning process, benefiting environmental protection and reducing the risk of detergent residues, thereby lowering the potential intake of harmful substances.

Frequently Asked Questions about Ceramic Non-stick Coatings

Q1: How is the temperature resistance of ceramic non-stick coatings?

Inorganic ceramic non-stick coatings exhibit excellent temperature resistance, including high temperature and thermal stability.

Generally, the temperature should not exceed 260°C when using water-based fluoropolymer non-stick coated cookware, whereas ceramic non-stick coatings remain stable and do not decompose at temperatures up to 450°C. This is particularly important for cooking methods requiring extremely high temperatures.

The exceptional thermal stability of ceramic non-stick coatings also ensures that their physical and chemical properties remain unchanged during repeated heating and cooling cycles, ensuring the durability and safety of the coating for daily use of cookware.

Pfluon closely monitors the thermal stability of its ceramic non-stick coating products. Our product standard "Q/PFL-003-2022" also includes tests for coating thermal shock resistance, ensuring the thermal stability performance of each product.

Q2: Are ceramic non-stick coatings healthy and environmentally friendly?

As mentioned earlier, ceramic non-stick coatings are made by combining organic and inorganic substances, which can fully decompose in nature and possess high thermal stability and surface hardness, ensuring the safety of home cooking.

We promise that Pfluon's ceramic non-stick coating products do not contain any potentially harmful chemicals, meeting current international food safety and environmental friendliness standards.

Pfluon's ceramic non-stick coating product series has passed various international safety certifications, such as FDA, LFGB, REACH, ROHS, etc., ensuring they do not contain any PFAS substances. This makes them a high-quality choice under the EU's new PFAS regulation.

Q3: What products can ceramic non-stick coatings be applied to?

Pfluon's ceramic non-stick coating product series includes the following products:

| Product Name | Non-stickiness | Abrasion Resistance | Corrosion Resistance |

| Ceramical | ★★★ | ★★★ | ★★★★★ |

| Ceramical Aero | ★★★★ | ★★★☆ | ★★★★★ |

| Ceramical Ultra | ★★★★★ | ★★★★ | ★★★★★ |

| PFLUON Amber | ★★★★★☆ | ★★★★☆ | ★★★★★ |

*Evaluations are based on data from Pfluon's product testing lab.

Ceramical and Ceramical Ultra are mature ceramic non-stick coating products from Pfluon, well-tested and recognized in the market. These two products can meet most of your product application needs, such as frying pans, baking trays, soup pots, electric frying pans, rice cookers, etc.

Ceramical Aero is a specially optimized product in the CERAMICAL series, designed for small appliance products. It meets the application scenarios and construction processes of small appliances, especially improving the flow and sag issues during the construction process of current air fryer products. If your products are mainly small appliances, consider this product.

PFLUON Amber is a major upgrade product officially launched by Pfluon this year. It utilizes Pfluon's latest PDS technology, promising to provide a revolutionary lasting non-stick experience. This product can also be applied to most cookware products.

Pfluon always adheres to the principle of providing the most suitable products for every customer. We will recommend suitable products based on your product conditions.

Additionally, if customers encounter difficulties with the construction process of ceramic non-stick coatings, our sales staff will provide detailed professional answers.

Q4: What colors can ceramic non-stick coatings be customized in?

Compared to water-based fluoropolymer coatings, ceramic non-stick coatings have a higher gloss and, thanks to their hard protective layer, maintain their unique color and gloss even after long-term use, with excellent resistance to yellowing.

Our ceramic non-stick coating products can meet your color customization needs from white, light to dark colors. With Pfluon's exclusive color management app "Optimal Collection," whether you prefer understated natural colors or vivid fashionable hues, you're sure to find colors that meet your needs.

Check Pfluon's color customization online app to customize your product's exclusive colors!

Q5: How are ceramic non-stick coatings applied?

As previously introduced, ceramic non-stick coatings are derived from the Sol-Gel process. To apply them to products, appropriate processing is required. The processing steps are as follows:

Substrate Pre-treatment

- Based on Pfluon's product information sheet, conduct degreasing, sandblasting, and dust removal on the substrate.

Coating Preparation

- Follow the processing conditions in Pfluon's product information sheet, stir component A for more than 30 minutes, then mix with component B and mature for more than 8 hours, finally add component C and shake well.

Coating Application

Ensure the prepared coating is uniform without sedimentation through rolling, adjust the spray gun nozzle diameter according to the base oil and top oil (base oil: 1.0mm-1.3mm, top oil: 1.3mm-1.5mm), preheat the substrate, and spray the base oil-top oil. The recommended base oil to top oil ratio is 3:1-4:1. After spraying, keep the workpiece at 280°C~300°C for 10 minutes.

- *For detailed coating preparation processes and conditions, refer to "Pfluon Product Information Sheet."

We value every customer's experience with our products. If you encounter difficulties while using Pfluon products, we will dispatch technical personnel to provide on-site technical support as necessary.

That concludes the information on Pfluon's ceramic non-stick coatings. We hope this issue has answered some of your questions about ceramic non-stick coatings, making your selection and use of Pfluon ceramic non-stick coatings more comfortable and efficient. We look forward to continuing to share product knowledge with you, and supporting your business development.

Pfluon will continue to develop and update new non-stick coating products based on market feedback and the needs of every customer. Contact us directly if you have any questions!