Non-stick pans with PTFE coatings are recommended for use below 260°C, but why?

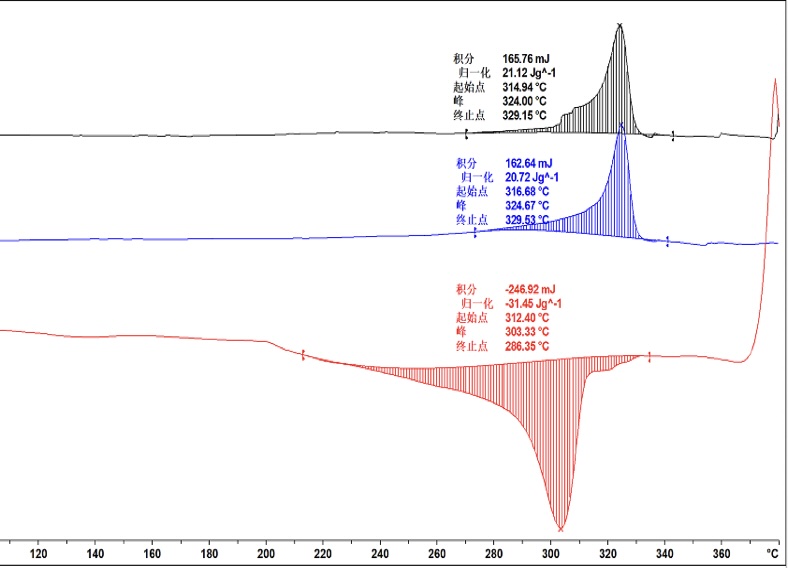

As shown in the PFLUON company's PTFE coating instrumental analysis curve, the black and blue curves represent the first and second transitions from low to high temperatures, completing the endothermic transformation between 314.94°C and 329.53°C; the red curve represents the exothermic transformation from high to low temperatures, completing between 312.40°C and 286.35°C. This can be popularly understood as a "mixed state of ice and water transformation, from ice to water and water to ice," except that "melted PTFE" flows poorly and has high viscosity, unlike water, and is not noticeably perceived due to other pigments and fillers. Taking this product as an example, 286.35°C is the critical point; beyond this temperature, the coating's performance degrades, and usability worsens. To ensure lasting performance, a safety margin is set based on the industrial safety standards, hence the recommendation for use below 260°C.

At what temperature does PTFE decompose into toxic gases in the air? Is the use of non-stick PTFE coatings really harmful under normal conditions?

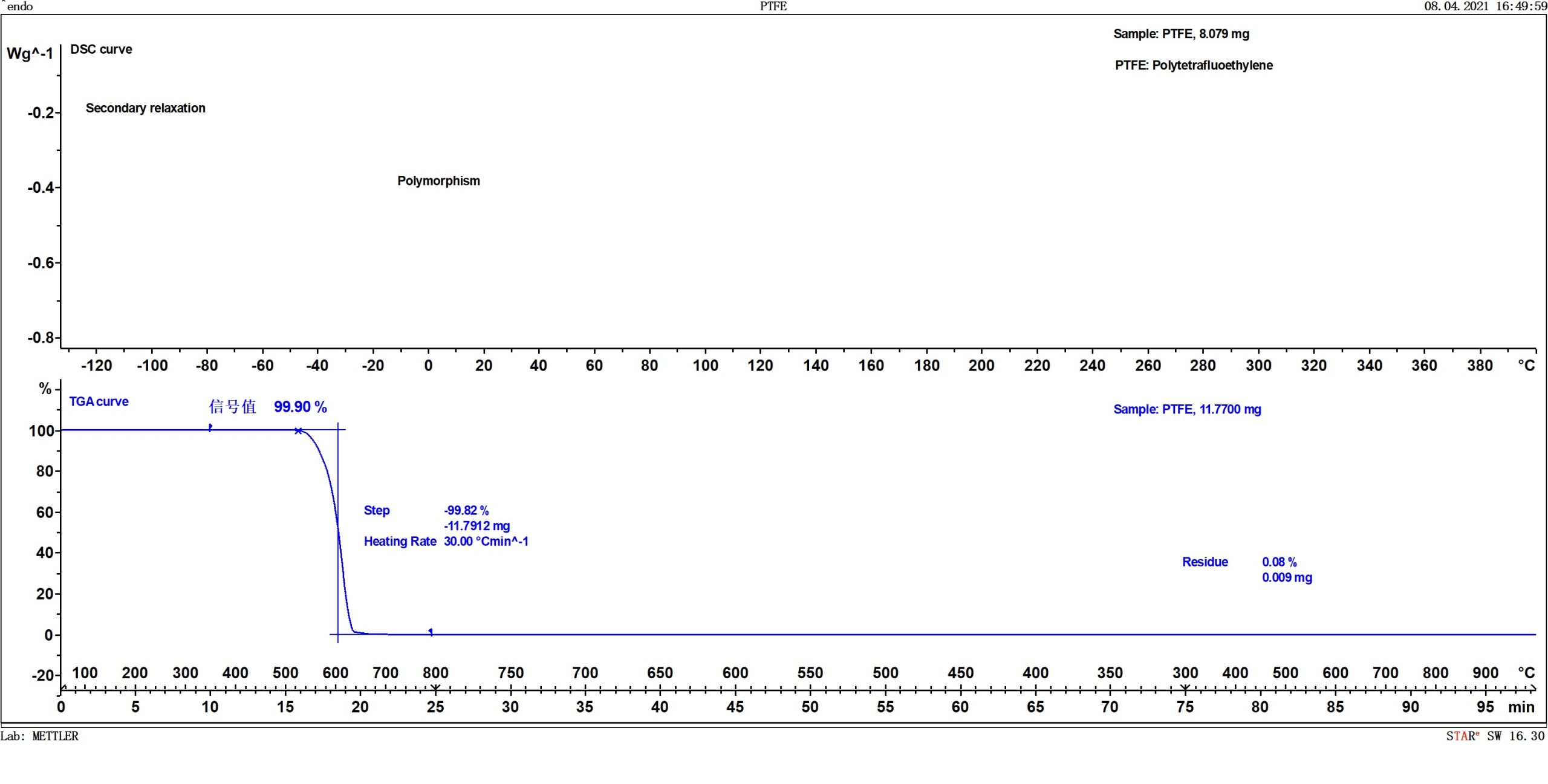

As illustrated, the PTFE decomposition temperature range is approximately 450-680°C, with instrumental monitoring indicating an initial decomposition temperature of 450°C and substantial decomposition (accumulating to 0.1%) occurring by 520°C. The rate of decomposition accelerates with temperature, peaking between 575-595°C. The smoke point of cooking oils typically ranges from 160-250°C, with ignition points between 300-460°C, and normal cooking temperatures are about 180-260°C. Research indicates that 180-220°C is healthier, reducing the production of smoke and toxic carcinogens and lowering the risk of lung cancer. Normal use poses no harm.

Can non-stick PTFE coatings be used at temperatures between 260°C and 450°C?

As the temperature gradually increases from >260°C to 450°C, the coating gradually softens, loses its adherence, and its scratch resistance, stain resistance, and non-stick properties diminish, leading to a continuous decline in user experience. However, the coating itself remains safe for human use. The smoke and toxic substances produced by cooking oils and food at high temperatures can harm human health. It is advised to avoid approaching the initial decomposition temperature of 450°C, especially continuous dry heating until the coating peels off and the pan burns through, which is not the intended use of cookware and should be strictly avoided.