PREMIUM

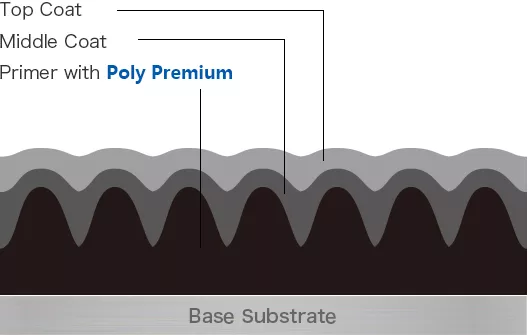

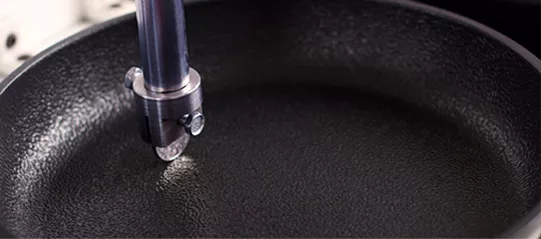

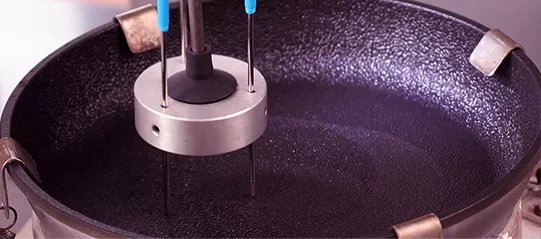

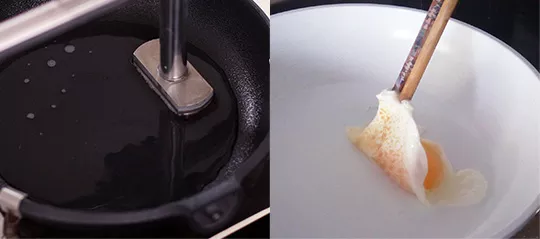

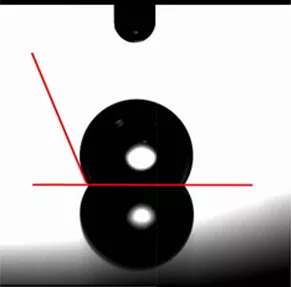

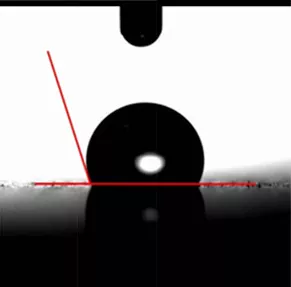

PREMIUM The series of coatings have excellent initial non adhesion and ultra long service life, and the product has excellent scratch resistance and wear resistance, making up for the shortcomings of existing coatings for cooking utensils in this function. It is a breakthrough and innovative technological highlight. A high-performance non stick coating product containing Primer, with various performance indicators significantly surpassing coatings such as ceramics and PTFE. PREMIUM Specially developed for high-end consumers pursuing ultimate performance.