Solution Provider of Medical Biomaterials

Scroll Down

Company Profile

As a subsidiary of Zhejiang Pfluon Technology Co. Ltd., Zhejiang Bio-PAEK Technology Co., Ltd. specializes in the R&D, manufacturing and sales of polymer biomaterials.

The Polymer Division of Pfluon has accumulated plenty of experience in chemical synthesis of PAEK, refining and purification, granulation and modification, injection molding and processing, profile processing, composite materials, application technology as well as other fields. On this basis, Bio-PAEK Technology has expanded the application of PAEK from industrial circle to medical biomaterials industry, thereby achieving the localization of medical biomaterials of PAEK .

Scientific Research Achievements

In 2019, Pfluon cooperated with Sir Run Run Shaw Hospital, Zhejiang University School of Medicine, Department of Chemical and Biological Engineering, Zhejiang University, Canwell MEDICAL Co., Ltd., Fudan University, Zhejiang University of Technology and Shanghai Jiao Tong University to jointly undertake the national key R&D projects of the Ministry of Science and Technology, i.e., Research and Development of Key Technologies for Mass Production of Medical PAEK Materials and Surface Biomimetic Modification Technology for Orthopedic Implants.

Therein, Pfluon is in charge of the sub-project Development of New Medical-grade PAEK Materials and Research on the Mass Production of PEEK. Four key technologies have been accomplished in this project, i.e., Precipitation and Granulation Technology in Polymeric Liquid Kettle, Key Technology of PEEK Purification, Preparation of PAEK with High Osteogenic Activity and Preparation of High-strength PAEK. Besides, it has passed nine tests of performance evaluation and biocompatibility evaluation (GB/T16886) in the standard specifications (YY0660-2008) of PEEK polymer for surgical implants. Currently, it is carrying out clinical trials of spinal fusion cage, and the project is scheduled to be accomplished in the first half of 2023.

Performance Strengths

Performance Advantages: PAEK is one of the most comprehensive and suitable biomaterials for human implantation, and it is a gift from heaven to mankind. PAEK enjoys the following nine performance advantages in comparison with metals or other polymers.

Elastic Modulus

Biocompatibility

Mechanical Strength

Wear Resistance

Thermal Conductivity

Fatigue Performance

Medical Imaging Performance

Disinfection property

Easy Molding and Processing Performance

Product Series

Implong - Long-lasting implants for a thriving future ahead.

Impshort - Short-term implants, yielding abundant results.

Oupshort - Optimized for widespread use, securing a fruitful future.

| Bio-PAEK Polymer Product Series | |||

|---|---|---|---|

| Product Name | Contact Time | Design Type | Product Form |

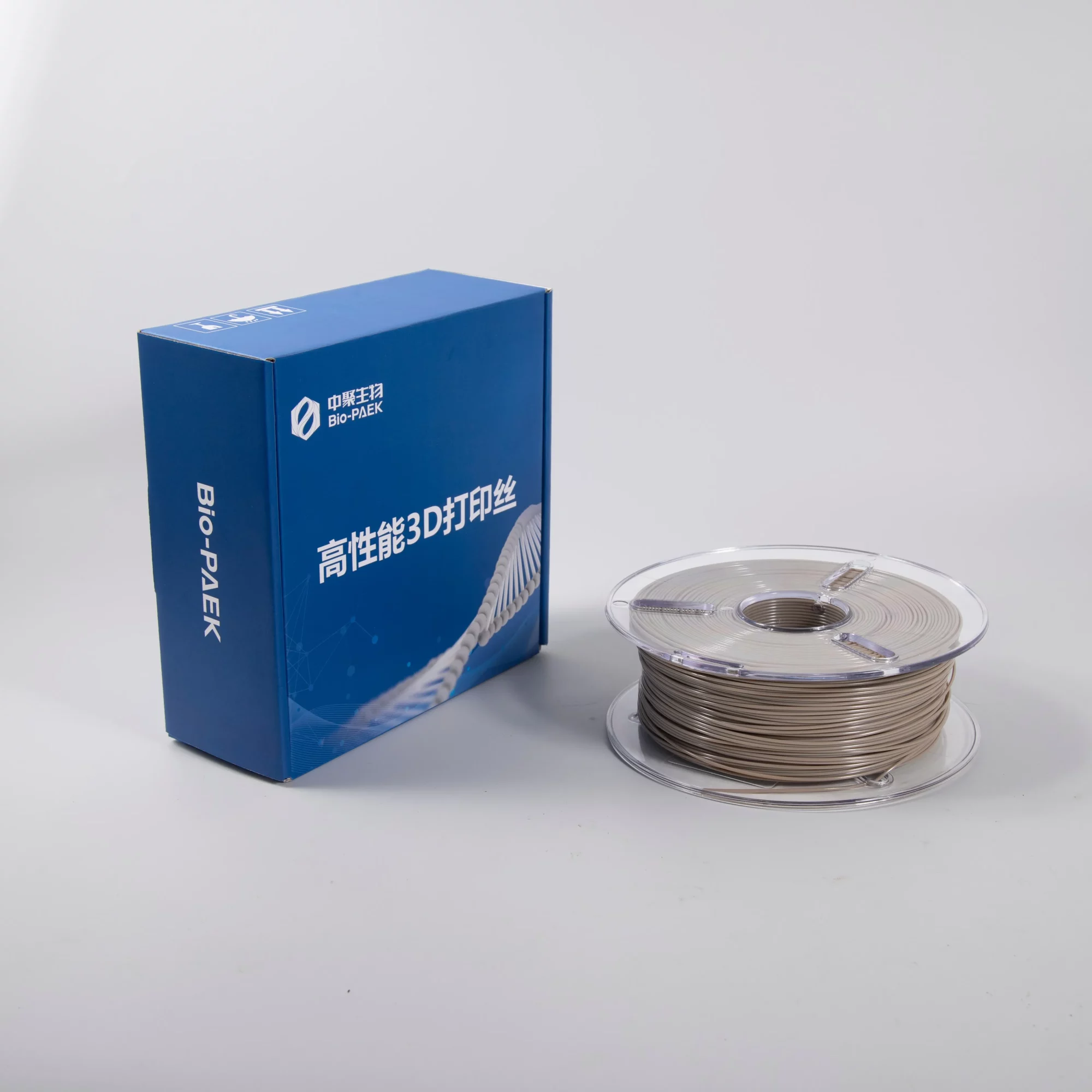

| Implong | Over 30 days of implantation | Long-term Implant | Powder, Granules, Filament, Sheet, Rod |

| Impshort | Less than 30 days of implantation | Extended Contact | |

| Oupshort | Short-term Contact | Partial Short-term Contact | |

In order to achieve commercial production, Zhejiang Bio-PAEK Technology Co., Ltd. has built PAEK R&D center, medical biomaterials laboratory, 600 square meters of class 10000 clean room, double screw granulator for imported medical materials, single screw extruder for imported medical materials, medical material annealing oven, medical PAEK unidirectional tape prepreg production line, etc. And based on the advanced hardware facilities, we has established ISO13485 quality management system.

Based on the project of “Key Technologies for Mass Production of Medical PAEK and the R&D of Surface Biomimetic Modification Technology for Orthopedic Implants” by the Ministry of Science and Technology, We will continue to conduct comprehensive testing of the performance evaluation and biocompatibility evaluation (GB/T16886) for Standard Specification for Polyether Ether Ketone Polymer for Surgical Implants in Industrialized Biomaterial Products (YY0660-2008). At the same time, we will apply for the document filing in the Medical Device Evaluation Center of the National Drug Administration. And we will cooperate with leading domestic PAEK orthopedic implant device manufacturers to make domestic medical PAEK to enter the market for services.